Project Extension with ARaymond China

About ARaymond

ARaymond is the global partner of choice for automotive OEMs’ and tier-1 suppliers’ fastening and assembly needs.

About Projects in Europe

In 2019, the headquarter of ARaymond implemented a TEEXMA QMS system in Grenoble, France in order to enhance their quality management system from quality to manufacturing. After the Success of the 1st phase, this QMS system has been extended to other plants in France and Germany.

Project Extension in China

ARaymond group made the decision to extend the QMS project to their plant in China. By the end of 2019, BASSETTI China made a complete study with their China plant and generated a clear specification of their technical needs. Nowadays, BASSETTI project team is customizing the TEEXMA QMS application based on ARaymond China’s requirement. It will be delivered to the client in 4 phases with the technical training and on-site implementation by the end of May.

Several Key factors for a successful project

Study

The engineering background of BASSETTI project engineers ensure they have a deep understanding of the technical need for specific industry like automotive. They were not only collecting the information from the client but also leading them to better detect and structure the need.

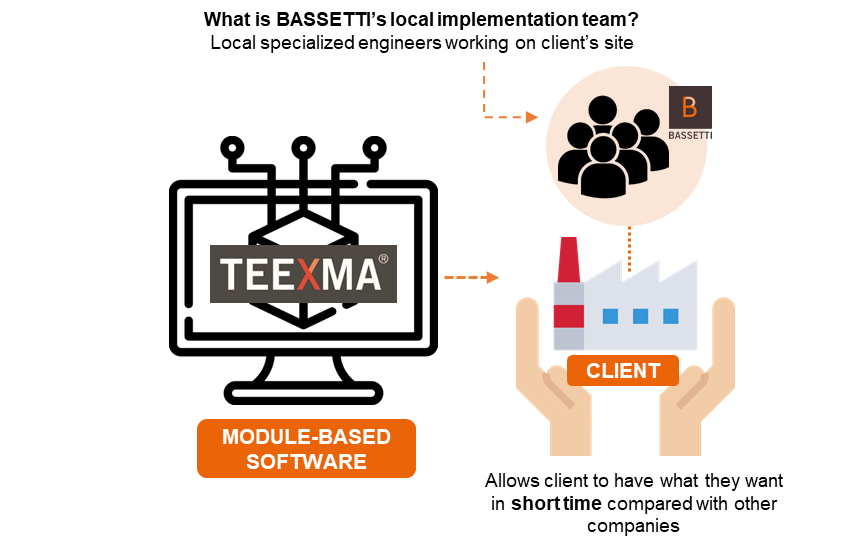

Customizable Modules

Thanks to the module-based structure of TEEXMA, BASSETTI can configure the system based on the existing application from France and then adapt it to the needs of China.

Local implementation

Adapt to the process of the customer - Easily complete your needs on-site

Follow up - Quick response from our team to deal with changes and updates based from the client's feedbacks.

More deliveries, Easier communication - Engineers can match the needs of the clients faster, with no mistakes.

For more information